Skoda Fabia 2 Workshop Manual

. Service Workshop Manual FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Edition 08.99 Engine code AUA AUB BBY BBZ BKY Service Department. Technical Information Printed in Czech Republic S00.5306.00.20. Service The Workshop Manual is intended only for use within the Organisation Škoda. Printed in Czech Republic S00.5306.00.20 It is not permitted to pass it on to other persons. © ŠKODA AUTO a. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components List of Supplements to Workshop Manual FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Edition 08.99 Suppleme Edition Subject Article Number 08.99 Basic Edition S00.5306.00.20 07.00 Supplement to Basic Edition S00.5306.01.20 05.01 Modifications in Rep.

Free PDF Downloads for all Engine sizes and models for Skoda Fabia. Skoda Fabia Service and Repair Manuals. Skoda Fabia Workshop Manual (260 Pages).

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components List of Supplements Edition 05.05 S00.5306.06.20. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Table of Contents 00 – Technical Data Technical Data.00-1 page - Engine number.00-1 page - Engine characteristics.00-1 page 10 – Removing and Installing Engine Removing and Installing Engine. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Parts of the Cooling System. 19-1 page - Parts of the cooling system fitted to body.19-1 page - Coolant regulator - Summary of components. 19-1 page - Coolant pump - Summary of components. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 00 – Technical Data 00-1 Technical Data Engine number The engine number („engine identification characters“ and „serial number“) is indicated on the end face of the cylinder block at the gearbox side below the coolant ther- mostat housing.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Technical Data Edition 05.05 00-1 page S00.5306.06.20. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 10 – Removing and Installing Engine 10-1 Removing and Installing Engine Removing engine Special tools, test and measuring equipment and auxiliary items required ♦ Lifting device, e.g.MP 9-201- ♦ Tensioning block -MP 9-101- ♦. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Pull off hose -1- (for engines as of 04.02) and remove the engine guard -2- with air filter upwards -arrows. – Open cap of expansion reservoir to release pressure in the cooling system. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components ♦ Plug connection of the electric wiring to the radiator fans ♦ Plug connection of the thermo-switch -F18- ♦ Plug connection of the electric wiring to the main headlights and fog lights. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Continued for all vehicles – Disconnect earth strap of the gearbox.

– Release spring strap clamps and disconnect hoses of the coolant regulator housing: ♦ Heater intake hose ♦ Hose of the expansion reservoir ♦. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Release screws -arrows- from engine mounting -A- and from the gearbox mount -B. – Lower engine/gearbox unit and push towards the front.

Note The engine/gearbox unit must be guided carefully so as not to damage the body. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Secure engine/gearbox unit in the engine and gear- box mount -arrows- and tighten the screws to the indi- cated tightening torque ⇒ 10-1 page 7.

– Position the vent hose for the coolant reservoir on the ventilation tube and draw together with retaining clips. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components ♦ Plug connection of the electric wiring to the radiator fans ♦ Plug connection of the thermo-switch -F18- ♦ Plug connection of the electric wiring to the main headlights and fog lights –. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components ♦ Do not use degreased parts. ♦ Unless otherwise indicated the following tightening torques apply: Component Torque Bolts, nuts 9 Nm 13 Nm 20 Nm 40 Nm M 12 70 Nm deviations: ⇒.

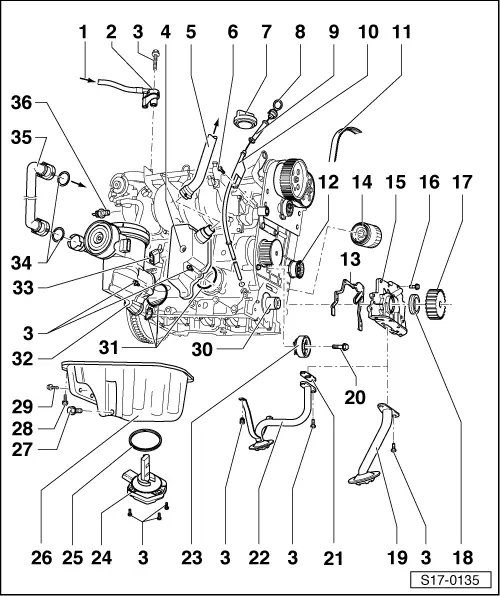

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 13 – Crankgear 13-1 Disassembling and assembling engine Summary of components of ribbed V-belt on vehicles fitted with AC 1 - Tensioning pulley for ribbed V-belt Swing out the tensioning pul- ley with ring spanner. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Removing and installing V-ribbed belt Special tools, test and measuring equipment and auxiliary items required ♦ Clamping lever -MP 1-203- Vehicles with air conditioning Routing of the V-ribbed belt Belt drive with AC compressor. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Position clamping lever -MP 1-203-, secure by insert- ing a pin and and push AC generator towards the crankshaft.

Remove the released ribbed V-belt from the AC genera- tor - belt pulley. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 13 - Crankshaft toothed belt sprocket pay attention to position of toothed belt when installing ⇒ 13-1 page 4 14 - 12 Nm replace 15 - V-ribbed belt pulley pay attention to locating element when installing removing and installing ⇒. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Removing – Pull off hose -1- (for engines as of 04.02) and remove engine protection -2- with air filter upwards -arrows. – Remove V-ribbed belt ⇒ 13-1 page 2.

– Remove top toothed belt guard. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Install supporting device -MP 9-200- according to the illustration. – Remove the top securing screw from the bottom toothed belt guard below the engine mount. MP 9-200 – Release the coolant expansion reservoir and lay aside. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Insert the two fixing pins through the locating holes of the camshaft sprockets up to the stop in the fit holes in the cylinder head cover. Note The two fixing pins are correctly inserted if the end parts -D- are flush with line -A.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Mark the pointer position of the tensioning pulley -1. Load timing belt by firmly pressing down with thumb -arrows. The pointer must move. – Relieve the toothed belt again.

– Turn the crankshaft two turns in the running direction of the engine. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Procedure – Position crankshaft on TDC cylinder 1. The chamfered tooth must correspond with the marking on the sealing flange -arrow. – Fit the coupling drive - toothed belt. If the toothed belt has been used pay attention to the rotation direction. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Loosely fit the tensioning pulley with the fixing screw and turn with the Allan screw in the -direction of the ar- row.

– Tighten fixing screw manually. The recess of the base plate -1- must be positioned on the screw head -2- in the cylinder block. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Attach engine mount to cylinder block. Tightening torque 50 Nm.

– Screw the engine console to the body with screws -B. S13-0233 – Secure the engine console to the engine mount on the cylinder block with screws -A. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Disassembling and assembling engine Edition 05.05 13-1 page S00.5306.06.20.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 13-2 Removing and installing cylinder block Aluminium cylinder block WARNING! The crankshaft must not be removed. Merely re- leasing the crankshaft bearing cover will result in deformations of the bearing seats of the cylinder block. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 12 - Gasket replace 13 - Oil pump must be replaced completely when fitting pay attention to the driver on the crankshaft ⇒ item 15 must be positioned on dowel sleeves removing and installing ⇒ Chapter 17-1 14 - Gasket ring replace ⇒. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Press in gasket ring with pressure plate -T 10022/1- up to the stop. – Installing the main drive - toothed belt ⇒ Chap.

Removing and installing drive plate Special tools, test and measuring equipment and auxiliary items required ♦. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Check dimension -a- in three points and determine mean value. Specified value: 19.7.21.3 mm. Note The measurement is made through the hole of the drive plate to the milled surface of the cylinder block.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Screw 3 screws M6x35 into the threaded bores of the sealing flange -arrows. – Press out sealing flange together with rotor from the crankshaft by alternately screwing the screws into the sealing flange. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Grip assembly device -T 10017- or -T 10134- on clamping surface -B- of the threaded spindle in a vice. – Securing clip -A- from the new sealing flange (flange for assembly device -T 10017-). FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Lay the front side of the sealing flange on a clean and level surface. – Press the rotor -A- -arrows-, until it rests on the level surface. Note The top side of the rotor and the front side of the sealing flange must be flush.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Lay the sealing flange with the front side on theas- sembly device -T 10017- in such a way that the posi- tioning pin -A- sinks into the hole -B- of the rotor. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Unscrew hexagon nut -A- up to the end of the thread- ed spindle.

– Screw assembly device with Allan screws -A- up to the stop onto the crankshaft flange. – Screw in two M6x35 mm screws -A- by about 3 turns for sealing flange guide into the cylinder block. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components For assembly device T 10017: – Move the assembly cup -A- by hand in the -direction of the arrow- until the rotor -B- rests on the crankshaft flange -C. Guide bolts -D- on assembly device -T 10017- must at the same time sink into the thread- ed bore of the crankshaft. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components D - Inspecting the fitting position of the rotor on the crankshaft – Unscrew hexagon nut -A- up to the end of the thread- ed spindle. – Unscrew two M6x35 mm screws -B- from the cylinder block. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Tighten the new fixing screws of the sealing flange crosswise.

Tightening torque: 12 Nm. – Install engine speed sender -arrow. Tightening torque: 5 Nm. – Installing oil pan ⇒ Chapter 17-1.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 13-3 Disassembling and assembling piston and conrod 1 - Circlip 2 - Piston pin if stiff, heat piston to approx. 60°C removing and installing with driver -MP 1-304- 3 - Piston check ⇒ Fig. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Fig. 1: Inspecting piston ring gap clearance – Push in ring at right angles to the cylinder wall from the top through to the bottom cylinder opening, about 15 mm from the cylinder edge. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Fig. 4: Inspecting cylinder bore Special tools, test and measuring equipment and auxiliary items required ♦ Internal precision measuring instrument 50.100 mm – Measure at three points crosswise in a transverse di- rection -A- and lengthwise -B. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Disassembling and assembling piston and conrod Edition 05.04 13-3 page S00.5306.05.20.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 15 – Cylinder Head, Valve Gear 15-1 Removing and installing cylinder head Note ♦ When installing a replacement cylinder head, all the contact surfaces between the hydraulic supporting el- ements, roller rocker arms and the cams must be oiled before installing the cylinder head cover. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components for installing, clip onto hydraulic supporting element with locking clip 12 - Hydraulic supporting element do not interchange before installing, inspect axial play of the camshafts ⇒ Chapter 15-2 oil contact surfaces.

Skoda Fabia 2

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Engines with engine identification letters BKY 1 - Coupling drive-toothed belt before removing mark run- ning direction check for wear do not kink removing and installing, ten- sioning ⇒ Chapter 13-1 2 - 10 Nm. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 22 - Rear timing belt guard 23 - Cylinder head cover removing and installing ⇒ 15-1 page 4 turn (90 °) 24 - 10 Nm + torque a further replace Tighten crosswise from the middle outwards. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Release the screws at the noise insulation -arrows- and remove noise insulation. – Removing the two toothed belts ⇒ Chapter 13-1. Note ♦ The camshafts are located in the cylinder head cover. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components WARNING!

Wear protective gloves when working with sealant and grease remover! – Clean sealing surface on cylinder head and cylinder cover and remove sealant residues with chemical gasket remover. – Ensure that no dirt and sealant residues get into the cylinder head. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Further installation occurs in a similar way in reverse or- der to removal. Removing and installing cylinder head Special tools, test and measuring equipment and auxiliary items required ♦ Supporting device -MP 9-200- ♦. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components ♦ Vacuum hose from the brake servo unit to the intake manifold ♦ 4 pin plug connection from the intake manifold pres- sure sender under the intake manifold at front right and 2 pin plug connection from the knock sensor MP 9-200 ♦. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Insert the cylinder head.

Pay attention to the dowel pins in the cylinder block. – Insert new cylinder head bolts and tighten by hand. – Tighten the cylinder head bolts in the order shown as follows: –. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Testing the compression Special tools, test and measuring equipment and auxiliary items required ♦ Spark plug wrench, e.g.3122 B- ♦ Compression tester, e.V.A.G 1763- ♦ Extractor -T 10094- Test condition.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Install the spark plugs again and then tighten fully to 30 Nm. The further assembly is carried out in reverse order to disassembly. – Interrogate the fault memory ⇒ Vehicle Diagnosis, Measuring and Information System VAS 5051. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Removing and installing cylinder head Edition 05.05 15-1 page S00.5306.06.20. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 15-2 Repairing Valve Gear 1 - 20 Nm + torque a further turn (90 °) replace to release and tighten use tool -T 10016- ⇒ Fig.

1 in 15-2 page 2 2 - Camshaft sprocket. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 18 - Valve stem seal replace ⇒ 15-2 page 8 19 - Valve guide check ⇒ 15-2 page 7 20 - Oil pressure switch 0.03. 0.07 MPa (0.3. 0.7 bar) -F1-, 25 Nm inspect ⇒. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Fig.

2: Checking the axial play of the camshafts MP 3-447 Special tools, test and measuring equipment and auxiliary items required ♦ Universal dial gauge holder -MP 3-447- ♦ Dial gauge Carry out measurement with the cylinder head cover re- moved and the end covers installed ⇒. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Fig. 5: Reworking lower cylinder head sealing sur- face Permissible reworking dimension of cylinder head: a = at least 108.25 mm. Reworking valve seats Special tools, test and measuring equipment and auxiliary items required ♦. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components The max.

Permissible reworking dimension is shown in the figures for reworking the valve seats as dimension „b“. Reworking valve seats Reworking inlet valve seat = ∅ 28.7 mm = max.

Permissible reworking dimension = 1,5. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components ∅ Mill- ∅ Milling ∅ Mill- Valve seat ing cut- cutter ing cut- 90° ter 90° 120° ter 60° Inlet valve 21/34 Exhaust valve 21/34 120° Milling sequence 1 - Machine valve seat with 90° milling tool until until a perfect contact pattern is achieved. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Removing – Removing the two toothed belts ⇒ Chapter 13-1.

– Turn crankshaft slightly back. Note Camshaft sprockets must be interlocked with -T 10016- in the fit holes in the cylinder head cover.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Procedure – Insert valve into guide. End of valve stem must be flush with guide. Because of the different stem diame- ters only use inlet valve in inlet guide or outlet valve in outlet guide. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Connect pressure hose to compressed air (min. 6 bar overpressure (0.6 MPa)) and remove the valve springs with -MP 1-229. – Pull off valve stem seals with extractor -MP 1-230. Installing –.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Repairing Valve Gear Edition 05.05 15-2 page S00.5306.06.20. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 17 – Lubrication 17-1 Removing and installing parts of the lubrication system Note The engine oil level must never exceed the max. Marking - risk of damage to catalytic converter! ⇒ Inspection and Maintenance. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components pay attention to installation instructions on oil filter 15 - Oil pump with pressure relief valve, open for an overpressure of 0.45 MPa (4.5 bar) must be replaced completely when fitting pay attention to the driver on the crankshaft ⇒ item 30 must be positioned on dowel sleeves removing and installing ⇒. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components only for engines with the engine codes BBY, BKY and BBZ 34 - O-ring replace if damaged 35 - To induction pipe only for engines with the engine codes BBY, BKY and BBZ 36 - Oil pressure switch 0.03.0.07 MPa (0.3.0.7 bar) -F1-, 25 Nm. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Installing Note ♦ Pay attention to the 'use by date' on sealant.

Skoda Fabia 2 Prevodovy Olej

♦ The oil pan must be installed within 5 minutes after ap- plying the silicone sealant. ♦ The oil pan can be better and more securely installed if M6 threaded pins are inserted as guides in two loca- tions on the cylinder block flange. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Secure toothed belt gear -1- to the crankshaft with fix- ing screw -2. – Position crankshaft on TDC cylinder 1: The chamfered tooth of the toothed belt must correspond with the marking on the oil pump -arrow. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Position the bushing -T 10022- on the crankshaft and tighten the Allan screw of the inserting device -MP 1-207- by hand. – Insert new seal on the dowel sleeves -A.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Screw tester in the cylinder head instead of the oil pressure switch. – Connect brown cable of tester to earth (-). – Connect diode test lamp to battery positive and to oil pressure switch. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Removing and installing parts of the lubrication system Edition 05.05 17-1 page S00.5306.06.20. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 19 – Cooling 19-1 Parts of the Cooling Sys- Note ♦ When the engine is warm the cooling system is under pressure.

Before repairs, if necessary reduce pres- sure by opening the cap on the coolant expansion res- ervoir. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Inspect pressure relief valve with coolant system tester, e.g.V.A.G 1274- and adapter -V.A.G 1274/9- for leaks. Test pressure 0.14.

0.16 MPa (1.4.1.6 bar) 14 - Bracket for connector 15 - Bottom coolant hose. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Coolant regulator - Summary of components 1 - Spring strap clip 2 - Self-tapping screw, 9 Nm 3 - from bottom of radiator 4 5 6 7 8 9 10 11 ⇒ item 15 in 19-1 page 2. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Coolant pump - Summary of components 1 - Main drive-toothed belt before removing mark run- ning direction check for wear do not kink Toothed belt routing ⇒ Chapter 13-1 removing and installing, ten- sioning ⇒.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Connection diagram for coolant hoses 1 - Expansion reservoir 2 - Coolant pipe screwed onto the cylinder head cover 3 - Heat exchanger for heating 4 - ATF radiator only for vehicles with auto. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Open drain valve -arrow- at radiator. Note Observe the disposal instructions for coolant! Filling up – Close drain plug on radiator. – Install the noise insulation. Select the appropriate coolant additive from the electron- ic original spare parts catalogue Škoda or from the list of. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Disconnect the connector plug from the thermo-switch -F18.

– Remove lock carrier and lay aside ⇒ Body Work; Rep. – Release the fixing screws of the radiator and remove together with fan shroud and fan.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Note ♦ The integrated gasket of the coolant pump must not be removed from the pump. ♦ If leak and damage present, replace the coolant pump with gasket completely. ♦ Cover the toothed belt with a cloth before removing the coolant pump in oder to protect it from the coolant.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 20 – Fuel Supply 20-1 Removing and installing parts of the fuel supply system Note ♦ The fuel supply system must be bled after removal of the fuel filter, fuel delivery unit and the fuel rail. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components as spare parts in the kit with a new gasket ring ⇒ item 9 and O-ring ⇒ item 10 after replacing the fuel filter, bleed ⇒ 20-1 page 10 the fuel supply with the valve on the fuel strip. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Fig. 1: Installation position of flange of fuel deliv- ery unit Marking on the flange must be aligned with marking on the fuel tank -arrows. Blue return-flow line -1- on the connection with the mark- ing -R. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components ♦ Carefully cover or close opened components if the re- pair is not completed immediately.

♦ Only install clean parts: Remove spare parts from their wrapping immediately before fitting. Do not use any parts which have been stored unwrapped (e.g. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Note ♦ When inserting the fuel delivery unit, ensure that the fuel gauge sensor is not bent. ♦ Moisten the gasket ring of the flange with fuel before fitting. ♦ Make sure the fuel hoses fit tightly.

Zadne Bubny Skoda Fabia 2

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Fold the rear seat forwards. – Remove the fuel delivery unit guard and disconnect the plug connection from the fuel delivery unit flange. – Removing rear axle ⇒ Running Gear; Rep. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components ♦ Pressure gauge appliance, e.g.V.A.G 1318- ♦ Adapter, e.g.V.A.G 1318/1- ♦ Adapter, e.g.V.A.G 1318/11- ♦ Adapter, e.g.V.A.G 1318/17- ♦ Adapter, e.g.V.A.G 1318/23- ♦ Torque wrench ♦ Measuring vessel ♦. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components If no open circuit was detected: – Replacing fuel delivery unit ⇒ 20-1 page 4. Inspecting fuel flow rate Test conditions. Supply voltage OK.

Remote control -V.A.G 1348/3A- is connected. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Check the fuel lines for possible diameter restrictions V.A.G 1318 (kinks) or blocking. V.A.G 1318/11 – Disconnect hose -1- of the feed line from the fuel filter inlet (filter version with integrated fuel pressure regu- V.A.G 1318/1.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Vent the fuel system – Remove cover from the fuse holder. – Remove fuse No. 61 from the fuse holder. – Connect remote control -V.A.G 1348/3A- with the adapter cable combination from the adapter cable set in fuse holder 61 and to positive terminal of battery (+). FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Screw adapter -V.A.G 1318/20-1- onto adapter -V.A.G 1318/20. – Turn the valve (at T-union) anti-clockwise, until it is ful- ly opened. – Screw adapter -V.A.G 1318/20- fully onto the vent valve.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Connect the pressure gauge -V.A.G 1318- with adapt- V.A.G 1318/11 er -V.A.G 1318/11- and -V.A.G 1318/17- to the fuel V.A.G 1318/17 feed line, the shut-off cock on the measuring device must be in position -A. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components WARNING! Maximum pressure of the fuel delivery unit is 7 bar (0.7 MPa). If this pressure is reached the fuel deliv- ery unit may be damaged.

If the nominal value of min. 3 bar (0.3 MPa) is reached: –.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Open shut-off cock on the measuring device -position – Activate the remote control and simultaneously close the shut-off cock in the measuring device in position -B. – If a pressure of min. 3 bar (0.3 MPa) is reached, dis- connect the remote control and observe the drop in pressure on the manometer.

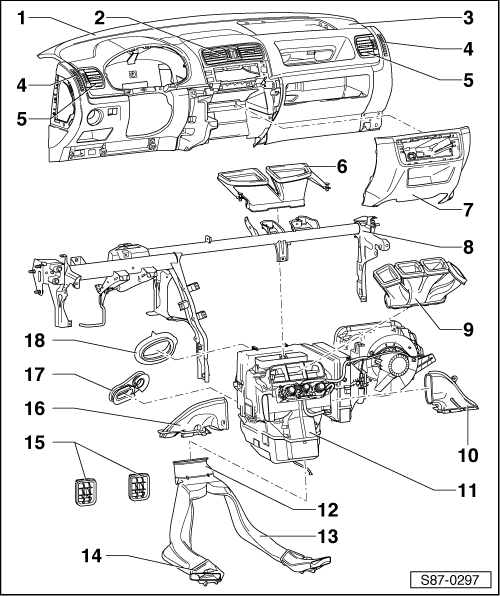

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 20-2 Inspecting Electronic Power Control (Electronic throttle) Summary of components 1 - Bracket removing and installing ⇒ Running Gear; Rep. 46 2 - Connecting plug black, 6 pin 3 - Accelerator pedal position sender (-G79- and -G185-) inspect ⇒. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Inspecting Electronic Power Control (Electronic throttle) Edition 07.00 20-2 page S00.5306.01.20.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 20-3 Activated Charcoal Filter System Summary of components of activated charcoal filter system Note The hose connections are secured with spring strap clamps or quick strap clamps. Observe the safety precautions ⇒ Chap. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Activated Charcoal Filter System Edition 07.00 20-3 page S00.5306.01.20. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 26 – Exhaust System 26-1 Removing and installing parts of the exhaust sys- Note ♦ When performing installation work on the exhaust sys- tem, make sure the exhaust system is not mounted under tension and has adequate clearance from the vehicle body. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 9 - Lambda probe after catalyst -G131-, 50 Nm coat only thread with hot bolt paste -G 052 112 A3-; hot bolt paste must not get into the slot of the probe body inspect ⇒. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Exhaust manifold, front exhaust pipe with pre-catalytic converter and catalyst and component parts - Engine with engine identification characters BKY 1 - Hot air collector/shield 2 - 10 Nm 3 - Exhaust manifold.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Silencer with hangers 1 - 25 Nm 2 - Hanger Check fitting position 3 - Rear silencer Cylinder version as of 03.03 for first equipment building unit with front silencer, re- place individually when car. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Test conditions. Fuse No. 24 -arrow - must be O.K.

Exhaust system must be tight between the catalyst and the cylinder head. Coolant temperature minimum 80 °C. All electrical consumers, e.g. Lights and rear window heater, must be switched off. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components the catalyst need not necessarily be replaced, it need only be replaced if the next exhaust emission test fails or if there is visible damage to the catalyst.

If the exhaust emission test fails or if the catalyst is dam- aged: –. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components 26-2 Exhaust gas recirculation system Note The exhaust gas recirculation system is controlled by the 4LV control unit -J537- via the exhaust gas recirculation valve -N18- with exhaust gas recirculation potentiometer -G212. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Summary of components of exhaust gas recirculation - engine with engine identifi- cation characters BKY 05.05 1 - EGR valve -N18- with EGR po- tentiometer -G212- Inspect exhaust gas recircu- lation valve -N18- ⇒ 1.4/55.

FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components Test sequence – Disconnect the 6 pin plug from the EGR valve. – Switch on ignition. – Connect the multimeter for voltage measurement to contact 2 + 4 of the 6-pin plug. FABIA 2000 1.4/55; 1.4/74 Engine - Mechanical Components – Check wiring between the test box and the plug for in- terruption according to the Current Flow Diagram. Plug contact Bush to text box -V.A.G. 1598/31- Line resistance: max.

This is the default welcome page used to test the correct operation of the Apache2 server after installation on Debian systems. If you can read this page, it means that the Apache HTTP server installed at this site is working properly. You should replace this file (located at /var/www/html/index.html) before continuing to operate your HTTP server. If you are a normal user of this web site and don't know what this page is about, this probably means that the site is currently unavailable due to maintenance.

If the problem persists, please contact the site's administrator. Debian's Apache2 default configuration is different from the upstream default configuration, and split into several files optimized for interaction with Debian tools. The configuration system is fully documented in /usr/share/doc/apache2/README.Debian.gz.

Refer to this for the full documentation. Documentation for the web server itself can be found by accessing the if the apache2-doc package was installed on this server. The configuration layout for an Apache2 web server installation on Debian systems is as follows: /etc/apache2/ - apache2.conf `- ports.conf - mods-enabled -.load `-.conf - conf-enabled `-.conf - sites-enabled `-.conf. apache2.conf is the main configuration file. It puts the pieces together by including all remaining configuration files when starting up the web server. ports.conf is always included from the main configuration file.

It is used to determine the listening ports for incoming connections, and this file can be customized anytime. Configuration files in the mods-enabled/, conf-enabled/ and sites-enabled/ directories contain particular configuration snippets which manage modules, global configuration fragments, or virtual host configurations, respectively. They are activated by symlinking available configuration files from their respective.-available/ counterparts. These should be managed by using our helpers a2enmod, a2dismod, a2ensite, a2dissite, and a2enconf, a2disconf.

See their respective man pages for detailed information. The binary is called apache2. Due to the use of environment variables, in the default configuration, apache2 needs to be started/stopped with /etc/init.d/apache2 or apache2ctl. Calling /usr/bin/apache2 directly will not work with the default configuration. By default, Debian does not allow access through the web browser to any file apart of those located in /var/www, directories (when enabled) and /usr/share (for web applications). If your site is using a web document root located elsewhere (such as in /srv) you may need to whitelist your document root directory in /etc/apache2/apache2.conf.

The default Debian document root is /var/www/html. You can make your own virtual hosts under /var/www. This is different to previous releases which provides better security out of the box.